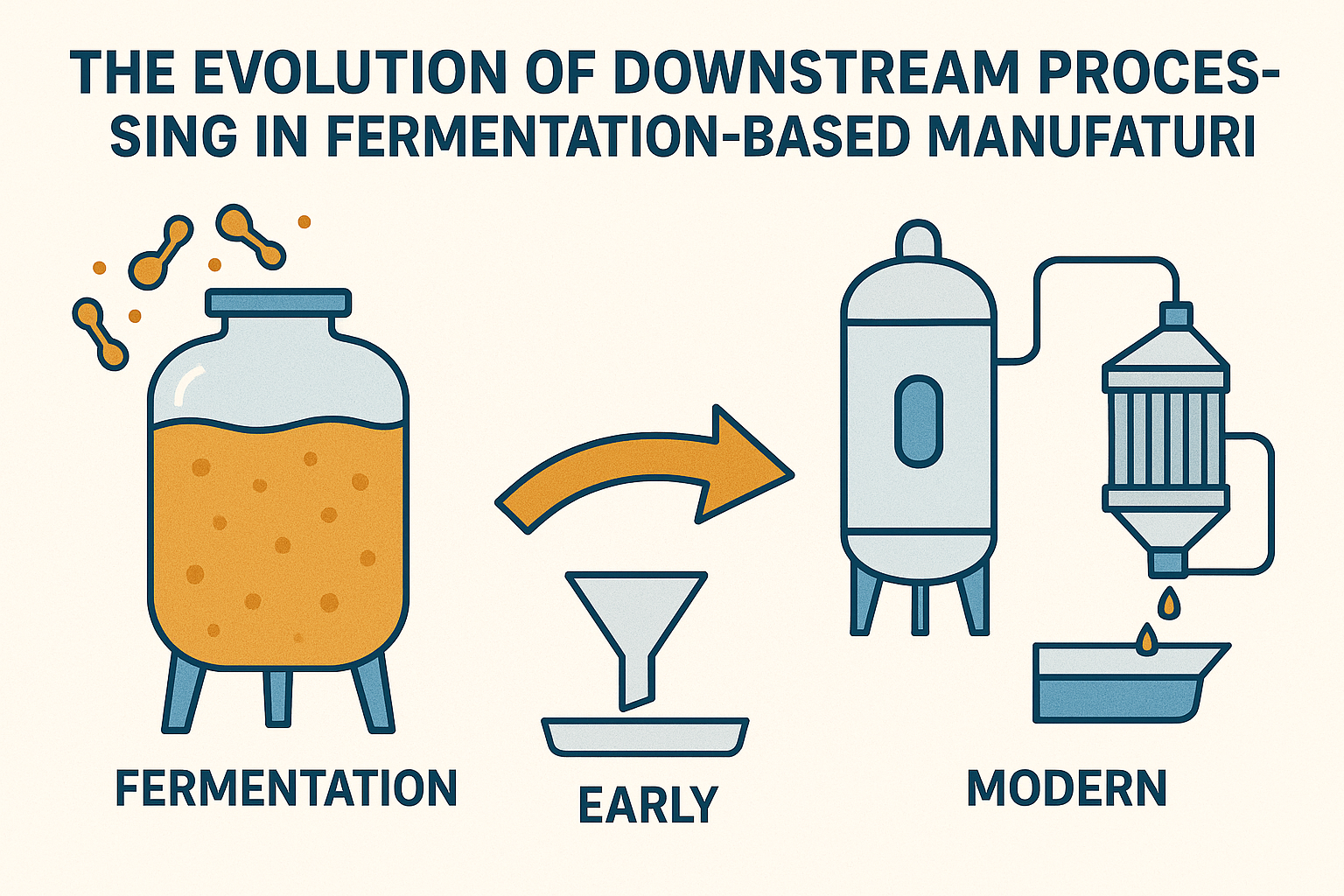

Downstream processing plays a critical role in the successful commercialization of fermentation-based products. Once the fermentation process itself is completed, the desired product must be efficiently recovered, purified, and stabilized to meet industry standards for quality and consistency. Over the years, downstream processing has evolved significantly, with technological advancements continuously improving efficiency, scalability, and cost-effectiveness.

Understanding Downstream Processing

Downstream processing refers to the series of steps involved in separating and purifying the desired product from the fermentation broth. These steps may include cell separation, product extraction, purification, concentration, and drying. Each stage presents unique challenges that must be addressed to ensure high product quality and yield.

Historically, downstream processing was often regarded as a bottleneck in fermentation-based manufacturing, as it could account for a substantial portion of the total production cost. However, innovations in equipment design, process optimization, and automation have greatly improved the efficiency of these processes.

Emergence of Advanced Techniques

As fermentation-based manufacturing expanded beyond traditional applications, new downstream processing techniques were developed to address emerging challenges. Chromatography, for example, became a widely used method for purifying high-value products such as antibodies, enzymes, and bioactive compounds.

Additionally, membrane-based technologies, including reverse osmosis and nanofiltration, have gained popularity for their ability to achieve high selectivity and purity. Advances in membrane materials and module design have contributed to improved efficiency and reduced operational costs.

Another notable advancement in downstream processing is the use of continuous processing techniques. Unlike traditional batch methods, continuous processing allows for uninterrupted product recovery and purification, enhancing productivity and reducing downtime.

Integration of Downstream Processing with Upstream Operations

To further improve efficiency, manufacturers are increasingly adopting integrated approaches that combine upstream and downstream processes. By designing systems that allow for seamless transitions between fermentation and purification, companies can achieve greater consistency and yield.

Process intensification strategies, such as inline monitoring and real-time process control, are also being applied to optimize downstream operations. These approaches help minimize product loss, enhance purity, and reduce overall processing time.

Challenges in Downstream Processing

Despite significant advancements, downstream processing continues to present challenges for fermentation-based manufacturing. The complexity of the purification process often depends on the nature of the product, often requiring specialized techniques to achieve high purity and stability.

Scaling up downstream processes can also be problematic, as techniques that work well at the laboratory scale may not be suitable for industrial-scale production. Additionally, the high cost of specialized equipment and consumables can be a barrier to commercialization.

Future Trends in Downstream Processing

The future of downstream processing in fermentation-based manufacturing is likely to be shaped by further innovations in automation, process integration, and data analytics. The use of artificial intelligence and machine learning to optimize purification protocols is expected to enhance efficiency and reduce costs.

As the demand for fermentation-based products continues to grow, companies like YDLabs are investing in state-of-the-art facilities that offer flexible and scalable solutions for downstream processing.

Conclusion

The evolution of downstream processing in fermentation-based manufacturing has been marked by continuous innovation and improvement. By adopting advanced techniques and integrating them with upstream operations, companies can achieve higher yields, greater purity, and enhanced efficiency. As technology continues to advance, downstream processing will remain a critical focus area for companies seeking to bring high-quality fermentation-based products to market.